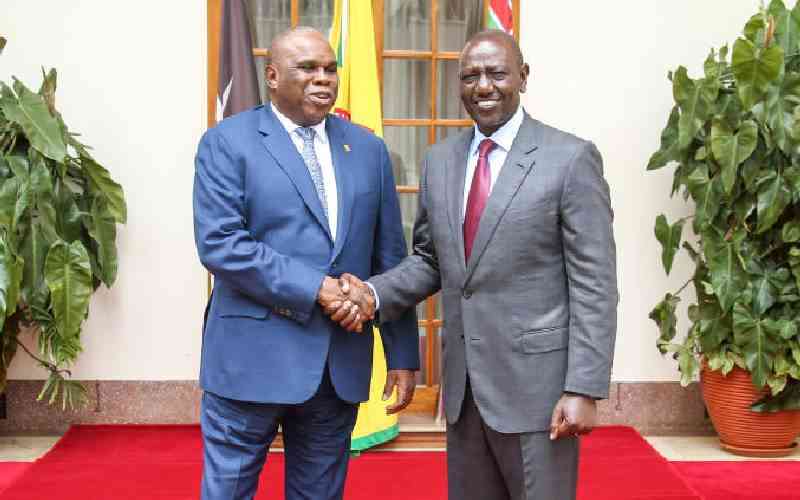

Kenya Association Of Manufacturers(KAM) CEO Anthony Mwangi speaking during Changamka shopping festival 2022 launch.[Wilberforce Okwiri,Standard]

×

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

The Standard Group Plc is a

multi-media organization with investments in media platforms spanning newspaper

print operations, television, radio broadcasting, digital and online services. The

Standard Group is recognized as a leading multi-media house in Kenya with a key

influence in matters of national and international interest.

- Standard Group Plc HQ Office,

- The Standard Group Center,Mombasa Road.

- P.O Box 30080-00100,Nairobi, Kenya.

- Telephone number: 0203222111, 0719012111

- Email: [email protected]

NEWS & CURRENT AFFAIRS

TV STATIONS

RADIO STATIONS

ENTERPRISE